Summary

The Energy3 megaUHTS is a modular thermal energy storage system capable of storing 40 MWh in a 40 foot shipping container and is charged using electricity. The Energy3 megaUHTS offers a low-cost route to mass energy storage on the giga-watt scale and CO2 reduction through conversion of existing thermal power plants. This conversion forgoes the need for new grid infrastructure and much of the expensive hardware to allow grid scale energy storage.

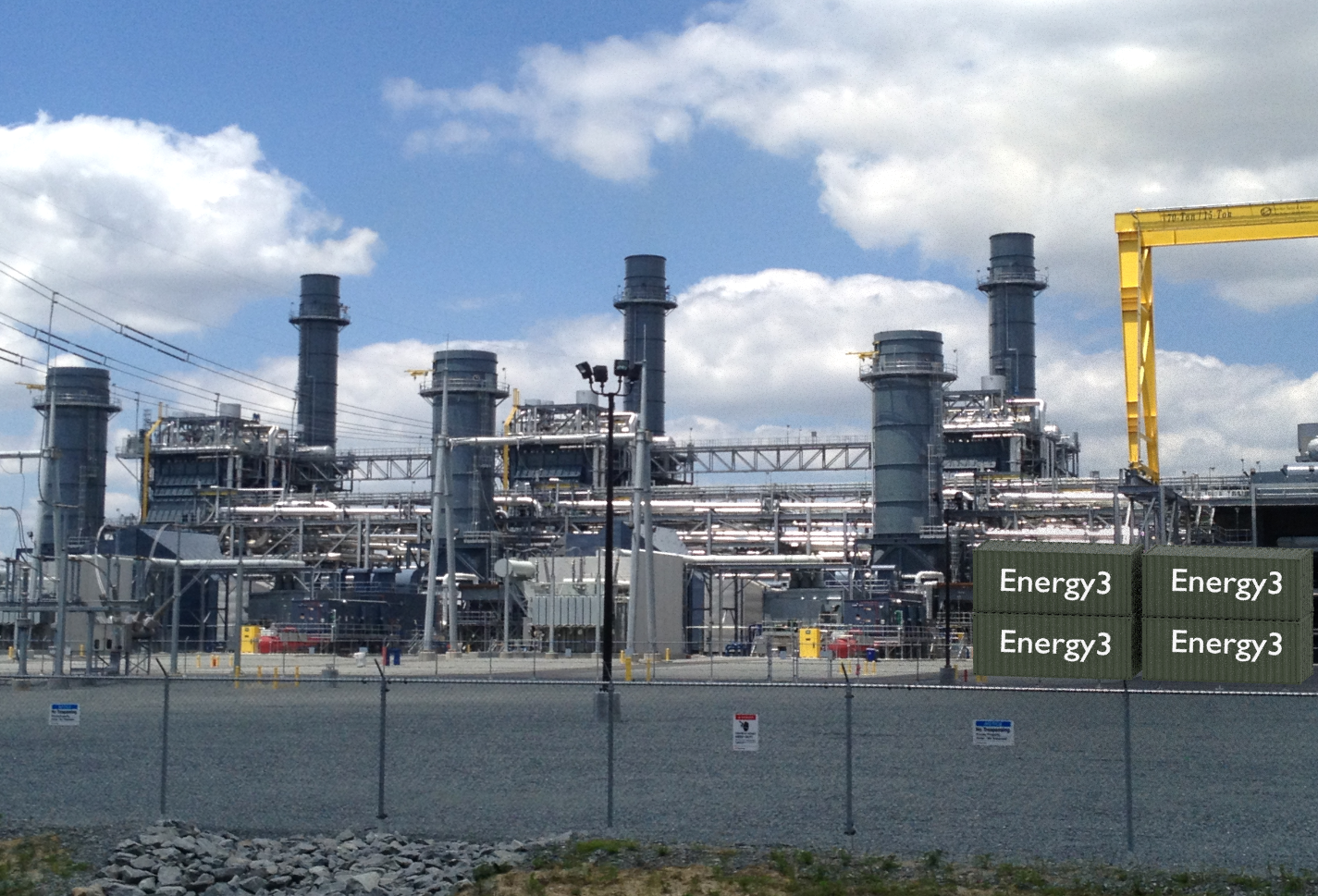

Early Stage Render

This work is derivative of "Combined Cycle Gas Fired Power Plant" by Peoplepoweredbyenergy, used under CC BY-SA 4.0.

Gas Turbine Conversion

The addition of an Energy3 megaUHTS thermal store between the compressor and combustion system of a gas turbine, allows gas to be preheated. This reduces the fuel requirements needed to reach turbine inlet temperature. Preliminary calculations predict the following fuel and consequent CO2 reductions for a variety of gas turbines:

- 1985 state of the art gas turbine (Turbine inlet temp (TIT) =1250°C) – fuel and CO2 reduction – 72%

- 1997 state of the art gas turbine (Turbine inlet temp (TIT) =1500°C) – fuel and CO2 reduction – 60%

- 2015 state of the art gas turbine (Turbine inlet temp (TIT) =1650°C) – fuel and CO2 reduction – 55%

This preheating also reduces nitrogen oxide (NOx) formation by decreasing the number of NOx hotspots. This is achieved by reducing the quantity of fuel in the combustion zone, which results in a leaner, more homogeneous, fuel-air mixture. Modelling work is currently under way to quantify the NOX reduction.

Steam Turbine Conversion

An Energy3 megaUHTS thermal store can eliminate the fuel use and CO2 generation of steam turbines. It does this by providing the stored heat at 900° directly to the steam generator.

Benifits

- This 40 MWh of thermal energy can be extracted as heat and hot water, or electricity if coupled with a gas or steam turbine.

- Can be integrated with district heating schemes to provide heating and hot water.

- The Energy3 megaUHTS can reduce the fuel costs of combined-cycle gas turbine operators by storing electricity when inexpensive and providing heat, in the place of fuel, when generation is required.

- This upgrade results in further emission reductions.

- Can retrofit existing combined-cycle gas turbines and steam turbines in increments of 40 MWh with simple modifications to combustion systems.

- Chargeable in 30 minutes with a 67 MW connection.

- Competing electrochemical energy storage systems that provide electricity have limited lifetimes (approximately 10 years). The thermal energy storage system is predicted to last 25 - 100 years.

Technology

The Energy3 megaUHTS is heated up to 900°C. A unique insulation structure ensures that so little heat escapes that the surface is safe to touch. Heat is extracted by a solid-to-gas heat exchanger. When needed, the heat from the Energy3 megaUHTS drives a turbine and generator to produce electricity.

Technical Details

- The core of the Energy3 megaUHTS has an energy density over 800 kWh/m3 exceeding existing electrochemical technologies

- Excellent thermal insulation with a maximum energy loss of 220 kWh per day, (less than 0.6% per day).

- Response time to produce electricity can range from 15 mins with a gas turbine to 45 mins with a steam turbine.

- Electricity generation efficiencies up to 62% due to high temperature storage.

- Fitted with low-pressure loss, high effectiveness, solid-to-gas heat exchangers.